If installing a floating floor, make sure that it has room to move. Increase the expansion gap up to 3/8″ (9.5 mm) in areas where the gapping is insufficient. Work on the gap around the perimeter by following the manufacturer’s specifications. Increase the Expansion Gap to the Correct Size You will need to remove all the furniture and baseboards before floating the subfloor, curing it, and replacing the floor. However, redoing the subfloor is a tedious job. If your floor has many humps or depressions, you need to use a filling compound to make it flat.Ĭopyright article owner is for this article. Note that a flat subfloor might not necessarily be level.

#Underlayment sound free#

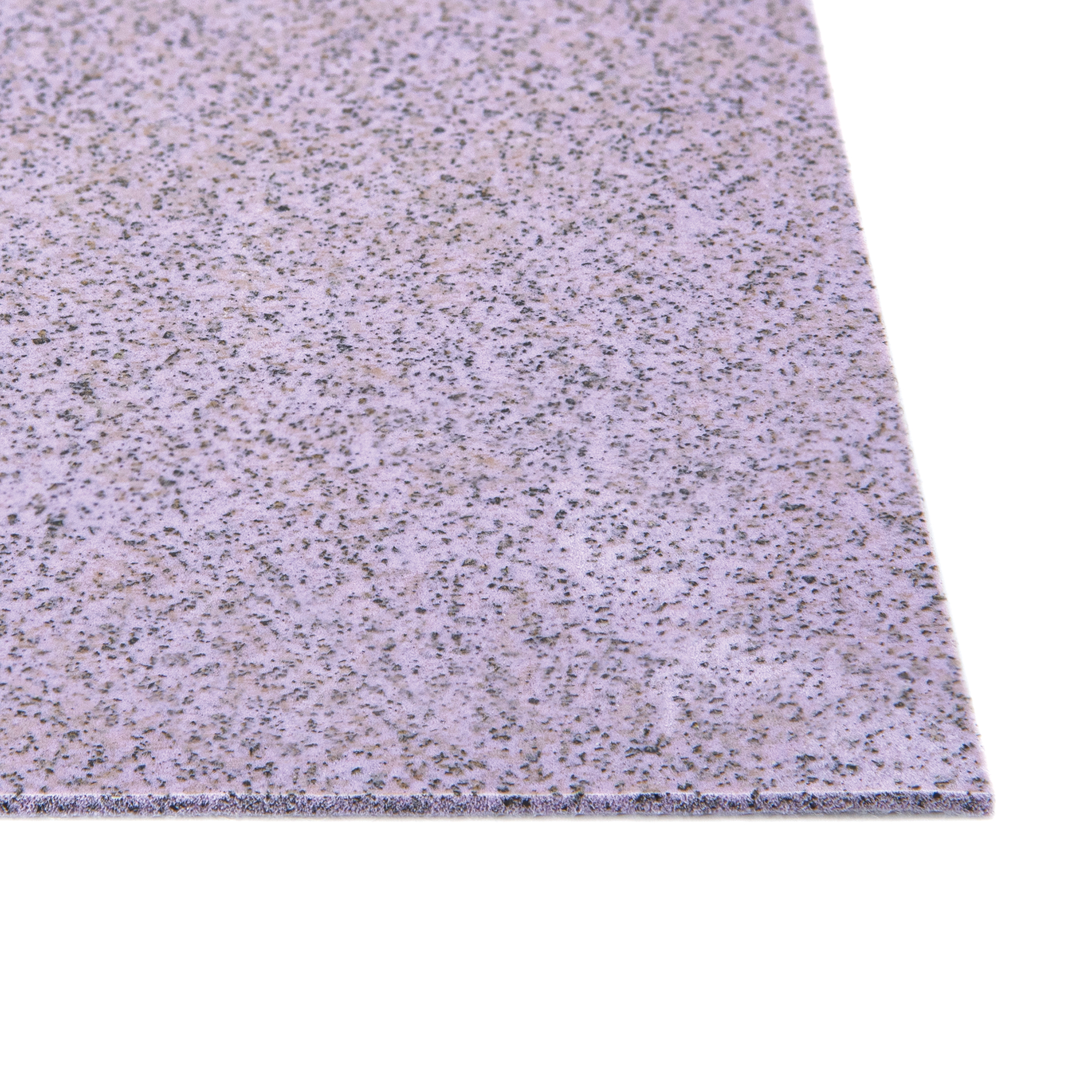

For a concrete subfloor, ensure it is level and free from dust and debris. If installing your flooring directly onto a plywood subfloor, prepare the subfloor by sanding the joists carefully and grinding the high spots. Ensure that the subfloor lies flat and smooth before you lay down your floor. If this is not done, your floor will not last long. If your subfloor was not flat before the flooring installation, remove the flooring as it’s hard to fix the subfloor when the floor is down. You can get rid of the noise on your vinyl floors by using the following techniques: Remove the Vinyl Flooring and Redo Your Subfloor Should You Fix Your Noisy Vinyl Flooring? If you don’t make room for expansion, your flooring can buckle too. The gaps are necessary because your floors expand if the morning is warm and contract in the cooler evening. Manufacturers specify the correct sizing for the expansion gaps. So, if you go ahead and use underlayment, squeaking noises may emanate from the vinyl backing rubbing against the underlayment. Note that some types of vinyl plank flooring do not allow underlayment of any kind. The movement leads to the foam underlay rubbing against the subfloor, thus causing the popping noises.Ĭopyright protected content owner: and was initially posted on. This problem also relates to a poorly prepared subfloor since the subfloor creates floor movement. The foam gets completely worn down as well. For instance, some types of foam underlayment rub so hard on the subfloor that with time, they create a white residue beneath the floor. The type of underlayment used on your subfloor could also create more noise than it dissipates. For example, a foam pad contains many small air pockets which pop when you squash it. You see, vinyl plank flooring typically comes with a foam, rubber, or cork padding attached, and the crackling sounds might come from this backing. However, this doesn’t always prove effective. Underlayment helps to absorb sound in areas with lots of foot traffic. This is because stress worsens when the floor is cool since it’s less flexible and moves more. Interestingly, when your house is hot and humid, the noise reduces. This movement stresses the joint between the plank and the subfloor and eventually leads to the floor, separating or cracking. When the subfloor is out of level, it moves. The noises will often come from an area where the leveling was not properly done. When installing vinyl plank flooring, subfloor preparation is crucial since all uneven spots need to be leveled. But you couldn’t be more wrong.īelow are some possible reasons why your vinyl flooring makes sounds that make you feel as though you are walking on rice crispies. Either that or your flooring is defective. If you installed your flooring, you might be concerned that you did something wrong, and that’s why your floor is noisy. These crackling, popping sounds lessen as the day wears on, the house gets warmer, and people walk across the floors more. In most homes, flooring noises are prevalent in the morning.

0 kommentar(er)

0 kommentar(er)